Người liên hệ : Rosa Liu

Số điện thoại : +86 18975107916

WhatsApp : +8618975107916

December 23, 2025

A leading logistics and warehousing company sought to overcome the limitations of their traditional lead-acid battery-powered forklift fleet. Challenges included long charging times, frequent battery swaps, high maintenance, and short lifespan, which hindered operational efficiency. To enable continuous high-intensity operations, reduce total cost of ownership (TCO), and support sustainability goals, the company implemented a "Lead-Acid to Lithium" upgrade, adopting our advanced lithium battery PACK solution.

![]()

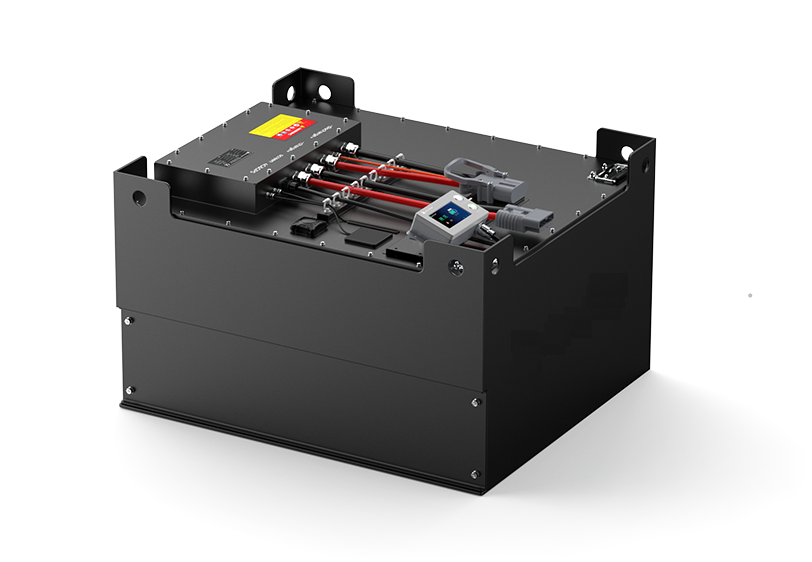

We designed and delivered a robust, high-efficiency lithium iron phosphate (LiFePO4) battery system tailored for electric forklifts. Key specifications include:

This project demonstrates the tangible economic and operational advantages of lithium battery conversion for material handling equipment. The shift from lead-acid to lithium is not merely a replacement—it’s a strategic upgrade that enhances productivity, safety, and environmental stewardship.

For existing forklift fleets, retrofitting with lithium packs offers a cost-effective path to modernization. For new equipment purchases, lithium power is now the clear technology of choice.

Transitioning from lead-acid to lithium represents a decisive step forward for the logistics and warehousing sector. Our lithium battery PACK solutions provide the reliability, efficiency, and intelligence needed to power the future of electric industrial vehicles.

Nhập tin nhắn của bạn